One overlooked issue that can occur with light poles is vibration. Light poles are upright shafted structures that will vibrate in certain conditions. Although it’s rare, acute pole vibration can be dangerous if the pole’s structure is compromised. Since light poles are ubiquitous and used in mostly public environments, it’s imperative to ensure they do not cause any safety issues.

The Dynamics of Light Pole Vibrations

Natural or man-made scenarios can cause light pole vibration. These include gusty winds, the deck “recoil” of a bridge or parking garage due to moving traffic, or the wind blast caused by a passing semi-truck.

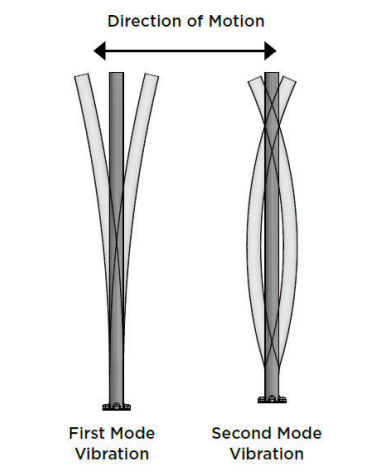

There are two main types of vibration:

- First mode vibration, aka harmonic vibration, occurs when high velocity gusts of wind cause the top of the pole to sway. Fortunately, light poles are designed to be flexible, and this type of vibration isn’t normally an issue unless the wind gusts are high (50 to 70 mph). This can cause stress at the base of the pole.

- Second-mode vibration, aka Aeolian vibration, is caused by an event called vortex shedding. Vortex shedding is triggered by continuous, high frequency, low-velocity winds commonly occurring in flat, wide-open areas with very few trees or buildings. This type of vibration is located at or near the middle of the pole which is then driven back and forth. Second mode vibration is a more serious issue than first mode vibration and can cause stress fractures, corrosion, and cracked lamps, among other things.

Causes and Contributing Factors

As stated above, wind and surface recoil can cause light pole vibrations but there are other things to consider.

- Pole shape – The shape and geometry of a light pole affect its susceptibility to vibration and its rate of vibration decay (reduction). Light poles with poor damping properties will sustain vibration for longer periods than others. For example, taller, slimmer poles tend to vibrate more easily and decay more slowly. Poles 20 feet or taller are more susceptible to vibration than shorter poles.

- Geography - Mountain passes and cities can create a wind tunnel effect which can lead to strong, sustained gusts. Coastal areas and the plains in the Midwest also experience high winds.

- Fixture load - Poles that have no luminaires or especially lightweight luminaires are susceptible to first mode vibration because they lack the weight to keep the pole from swaying.

The Effects of Vibration on Light Poles

Vibration causes lateral displacement. This will result in stress on the pole. stress occurs at the base of the pole. The greater the movement or displacement, the greater the stress will be. The constant repetition of these stresses is called fatigue or cyclic stress.

If applied over time and sufficient in degree, vibration can result in stress cracks in the pole. Pole vibration can also cause premature failure of components and lamps. Pole stresses, aka stress risers or stress concentration points, are much more intense at the base plate connection and hand hole. Because of their high stress concentrations at the corners, square poles are vulnerable to fatigue stress cracking.

How Vibration Affects Security Camera Poles Over Time

Environmental and Structural Causes

Security camera poles experience similar environmental forces as light poles. Constant exposure to wind, traffic movement, and mechanical equipment can introduce subtle but continuous vibration. These motions accumulate over time, transferring stress through the pole and camera mount.

Mechanical and Operational Impact

Ongoing vibration can lead to image instability, misalignment of the camera, and strain on fasteners or internal wiring. Small, repeated movements contribute to material fatigue, which can loosen hardware and shorten the lifespan of camera assemblies.

Detecting and Monitoring Pole Vibrations

Once a pole has been installed, inspect it at least once a year or more frequently if possible. The inspector should be close enough to touch the pole, which means a ladder or bucket truck will be required.

There are several methods for detecting first and second mode vibrations:

- First mode vibration: The pole can easily be observed swaying at the top. This isn’t unusual for a light pole but with high and/or gusty wind conditions, it can be dangerous if pole top displacement and whipping occur.

- Second-mode vibration: If caused by vortex shedding, vibration may be harder to detect. The scale of motion near the center of the pole may be tiny and not easy to perceive. An expert investigator who is trained to evaluate the situation must be at the job site to witness the condition when winds are blowing in the 8 to 25 mph range. In addition to seeing the motion, an investigator should be able to “feel” the vibration or detect it by placing a hand on the pole. Additionally, there might be noise such as conductors striking the inside of the pole. Accelerometers and chart recorders can be used for more sophisticated detection.

Specific areas of inspection include:

- All anchor bolts and leveling nuts must be present and well-secured.

- Hand hole cover and all fittings.

- The area of the pole shaft above and below the weld line.

- Take note of any rust or corrosion and ensure that all hardware at the top of the pole is accounted for and properly secured.

Mitigation Strategies and Solutions

There are several strategies for site assessment and pole selection to minimize vibration risks.

- Manufacturers must prevent integrating any sharp angles and notchesinto pole design. They can lead to fatigue cracks.

- Avoid dinging, scratching, and putting additional stress on the surface of the pole during transportation and installation. These defects will ruin the smooth finish and could prematurely weaken the pole’s strength.

Some light pole characteristics are recommended to lessen the effects of vibrations:

- Round Poles: In areas with prolonged vibration, round poles are a better option than square poles.

- Tapered Poles: These are preferred over straight poles.

- Steel Poles: Steel is preferred over aluminum due to its strength.

- Larger Diameter Poles: Choose poles with higher EPA (Effective Projected Area) capacities than required.

- Fiberglass Poles: These poles are resistant to first mode vibration due to their material.

To properly prepare for first-mode vibrations while planning a lighting project, it is important to calculate the pole’s loading requirements; follow local building codes; obtain the pole’s EPA; and adhere to the specified guidelines, wind maps, and standards.

What is EPA? It stands for the Effective Projected Area. EPA information is provided within the cut sheet specifications supplied by the pole manufacturer.

You can prepare for second mode vibrations by considering the location of the job site, as well as the pole’s shape and what it’s made of. The most vulnerable poles are square, straight aluminum poles. This is due to their corners and flat surfaces, plus the fact that aluminum isn’t as strong as steel.

Round, tapered steel poles are the least vulnerable to second mode vibrations. Their shape makes it easier for the wind to pass around them.

Options for preventing, mitigating, or alleviating damage from second mode vibrations are as follows:

- Install a vibration dampener.

- Change the location of the pole.

- Modify the landscaping to alter the wind pattern.

- Install a different pole type (shape and material).

Vibration Dampers: Types and Installation

A light pole vibration damper reduces the risk of damaging vibration. It adds mass and interrupts the natural frequency on the pole. Poles over 25 feet, especially square poles, should include a vibration damper.

First mode dampers reduce the sway of the pole.

- Square Pole Top Damper – A square aluminum fitting is placed atop the pole, replacing the pole cap. This can be applied to square steel or aluminum light poles to reduce sway.

- Ball in a Box - An epoxy-coated lead ball is put inside a box that is fastened at the top of the pole via set screws. Lead absorbs some of the resonant energy from the wind. The more balls you place in the box, the better they absorb energy. They can be installed in the field.

Ball in a Box and Hanging Chains are a type of impact damper. Impact dampers typically consist of some mass that physically contacts a surface in a repeated fashion, as often as needed, to attenuate motion. The quantity of mass can be tuned (most often added) to match the damping requirements of the structure.

Second mode dampers interrupt the natural frequency of the pole, minimizing the material fatigue caused by wind induced vibrations. It consists of a mass (usually a weight) attached to the structure. The damper’s natural frequency is tuned to match the structure’s vibration frequency. When the structure vibrates, the damper oscillates out of phase with the structure, dissipating energy and reducing vibration. For light poles, mass-tuned dampers can be added to reduce vortex shedding vibration caused by wind. These dampers help prevent excessive lateral movement, stress, and fatigue in the pole.

- Rod in a Canister – Rod in Canister dampers are placed inside the light pole. They can usually be identified by two bolts protruding on the outside of the pole. They are a type of inertia damper that counteracts the low amplitudes and higher frequencies associated with second-mode vibrations. They are usually factory-installed.

- Chain and Tube - A chain encased in a plastic tube runs two-thirds the length of the pole and disturbs the harmonic cycling of the shaft by randomly touching the inside surface of the pole. Any agitation caused by the wind transfers to the tube and chain. This style of dampener can be either factory or field-installed.

- Hanging Chain Damper – A chain damper consists of a PVC-coated chain hanging from a pole cap or connected using a through-bolt with spacers. This disrupts vibration by moving in the opposite direction of the shaft. They should not be used where the wiring is located near the top of the pole, as the chain could interfere with the wiring. The chain may create some noise. It is factory-installed.

- Snake Damper – A snake damper is installed through the pole’s hand hole to disrupt the vibration of the shaft. It can be field-installed.

LightMart's Vibration Defense Solutions

It is important to understand and address light pole vibrations before they become a dangerous problem. Our security camera poles and multi-purpose poles offer vibration-mitigating features like fiberglass material and round tapered shapes. We also offer vibration dampeners for square poles.

LightMart can help! Our light pole expertise can contribute to any outdoor lighting project. Contact us today!

David DeWald is the E-Commerce Marketing Specialist at LightMart. He has been working in the industrial and commercial lighting industry since 2013 and is based in the greater Chicago area. David specializes in digital product management, web content writing, and product marketing. He regularly publishes lighting industry-related articles on the LightMart blog. You can visit his LinkedIn profile here.